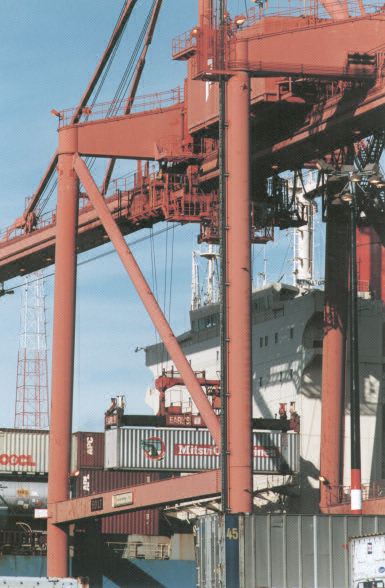

A container crane unloads a ship in the port of Seattle(text of audio follows photo) |

|

|

|

| Photo: Linda Becker | |

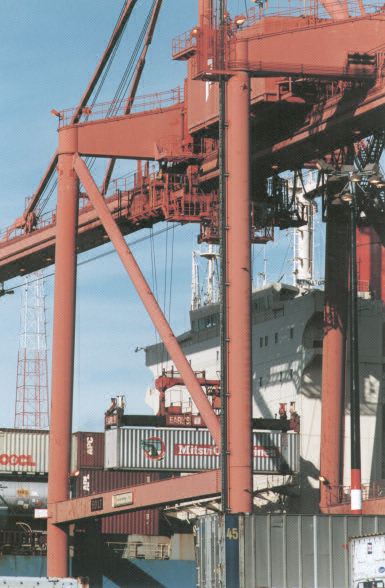

A container crane unloads a ship in the port of Seattle(text of audio follows photo) |

|

|

|

| Photo: Linda Becker | |

Narrator

On the Seattle docks, a huge orange gantry crane hunches over a container ship like a voracious insect, sucking the corrugated metal boxes up off the deck and spitting them down onto a procession of trucks, which pull up with a snort of jake brakes, take their load with a clank, and grind away.

Until the 1960s, loading and unloading ships was a slow, expensive process. Then, the emergence of container technology made it possible to rapidly shuttle standardized boxes from ship to train or truck and back again. The time required to unload and load a big ship imploded from upwards of a week to as little as eight hours.

Bob Middleton of the Port of Oakland recalls how the shipping business was transformed:

Bob Middleton

Very quickly, it became apparent that unless you bought boxes, you'd have to get out of it. On all the high-volume trade lines that was the case, with a vengeance, in the 60s and 70s.

Remember, the nature of container transit is, what it sells is speed and predictability. Virtually everything that goes in a box is something that is of fairly high value. The whole system evolved very quickly because it was a safe, fast, relatively cheap way to get stuff from continent to continent.

In other words, if you're moving commodities that aren't worth very much and your margin is razor thin, then unless you can get a very good deal in containers, you won't move them that way, you'd go some other route.

If, however, like the consumer goods that Americans are so familiar with and love so much and consume so much of, running shoes, electronics, food, clothes, furniture, automobiles, well, auto parts, anyway, it goes by box.

Narration and interviews by Peter Costantini

|

|